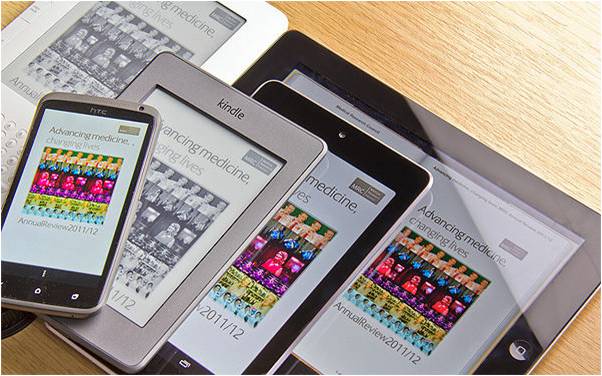

Mobile, seamless, and portable operations requirements are influencing the world’s trend of a multi-screen era. One person having multiple devices is already an unshakeable trend. Moreover, manufacturing more display screens means ITO material consumption. Consequently, finding ways to create environmentally friendly recovery mechanisms for display materials in the multi-screen era will be an important link for the industry’s sustainable development. Environmental ITO recycling technology is beginning this solution mechanism.

Second or third screen, means more ITO material consumption

Indium Tin Oxide ITO material is a type of indium oxide (In203), and when it is mixed with tin oxide (SnO2), the material is extensively used in all types of optoelectronic products, including all kinds of LCD display screens, touch panels, solar batteries, and antistatic coating. It is an extremely important key material that must be relied upon for plane electrical conductivity functions. According to statistics, Indium Tin Oxide (ITO) target materials account for 60-70% of all Indium use.

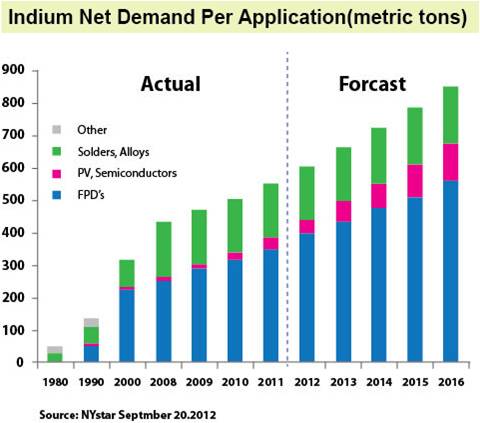

The Demand for Indium Metal is Soaring in the Multi-Screen Era

Minerals and metals market research organization, Nystar, predicts that panel display applications will continue to increase the demand for Indium metal and become the primary consumer market for Indium metal. Taking the touch panels on tablet computers and smart phones as an example, both capacitive touch and resistive touch require ITO film and ITO glass. Therefore, a very large amount of Indium metal is needed. On the other hand, manufacturing ITO for restive touch is highly difficult and only has a limited yield enhancement. This makes Indium materials even more precious.

At the same time, the cost of Indium is very expensive. Currently, it is valued at approximately US$600 per kilogram, and the main reason that the price remains high is that supplies are limited.

The Earth’s crust originally only contains sparse quantities of Indium metals, and the deposits are not found in independent mining deposits. It coexists with other trace elements in zinc mining deposits. Zinc metals must first be extracted before refined Indium ingot can be acquired. Currently China is the world’s leading producer of Indium; however, each year the amount that can be exported is restricted. Although other countries, such as the United States, Canada, and Japan, also produce it, in the multi-screen era there is no way that the supply level can keep up with amount in demand.

The amount of Indium tin oxide used in Taiwan accounts for approximately 1/3 of global consumption, and the overwhelming majority is concentrated in panel board and solar energy factories. From the perspective of global industrial competition, Taiwan has a demand for an extremely large amount, and at the same time, it is facing enormous competitive pressure. As a result, finding ways to increase efficient usage and recycling efficiency of Indium will have a direct positive benefit on lowering costs and increasing competitiveness.

Production Efficiency for Low ITO Recycling Ratios Is Becoming the Key to Competitiveness

However, under the current limitations of production technology, in an ion sputtering machine, ITO target materials only have a usability ratio of approximately 30%. The remaining 70% is for use of ITO target materials waste. Therefore, a recycling rate of between 60% and 65% for ITO target materials is another important source of Indium.

“When carrying out Indium plating, ITO glass and film must use a Metal-organic Chemical Vapor Deposition (MOCVD) method. Indium ions cannot directly hit the glass surface. A reflection method must be used in order to produce uniformly smooth ITO layers. Therefore, many Indium elements are wasted,” explained Kenny Hsu, Managing Director of UWin Nanotech.

On the other hand, the Indium recycling procedure that is currently in widespread use uses many acidic substances, which can easily damage ITO target materials. Furthermore, the waste water from stripping has a negative environmental impact.

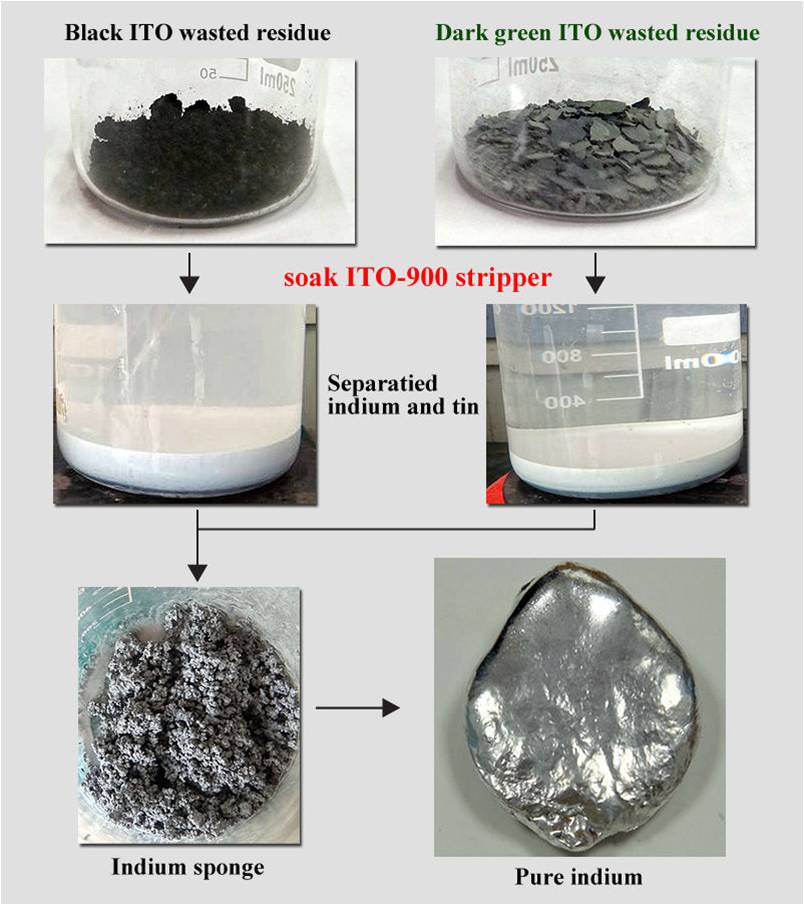

The ITO Indium recycling technology that is currently in widespread use mainly takes ITO waste target materials and pulverizes them into soluble mineral acids (hydrochloric acid or a mixture of hydrochloric acid and sulfuric acid to carry out dissolving) and uses an acid solution to separate elements, such as copper (Cu), lead (Pb), and tin (Sn). Then the Indium and tin are separated using electrolytic refining. The main difficulty is separating the Indium and the tin.

In order to increase the recycling efficiency for Indium metals while also reducing the pollution created during the recycling process, UWin Nanotech has researched and developed an environmentally friendly Indium tin oxide stripping prescription – ITO-900.

Managing Director Kenny Hsu states that the ITO-900 Indium tin oxide stripping prescription is a specialty product for carrying out Indium tin oxide stripping for industries such as electro-optical and panels, which use ITO cladding materials or residue in their production processes. It has broad applications for ITO cladding materials for substrates made of nickel, copper, titanium alloys, porcelain, stainless steel, or glass.

The ITO-900 Stripping Prescription Satisfies Indium Tin Recycling Needs for the Multiscreen Era

Due to the widespread use of substrate materials, ITO-900 can satisfy Indium tin recycling needs for diverse display and opto-electronic technologies in the multi-screen era. Only a single stripping prescription is needed in order to carry out recycling for diverse types of waste materials.

More importantly, the ITO-900 stripping prescription also has the advantages of all UWin Nanotech products. It is green and environmentally friendly and completely in compliance with contemporary demands for ecological and environmentally friendly sustainable development.

“ITO-900 does not contain toxic or harmful materials, such as cyanide or halogens, and its waste water treatment is very simple,” said Kenny Hsu.

At the same time, besides satisfying environmental protection demands for industrial development and business operations, its economic benefits are its most important features. In fact, they are the most direct benefits that the ITO-900 Indium tin stripping prescription provides.

According to UWin Nanotech’s experiments, each liter of ITO-900 formula can handle approximately 300-400g of ITO waste residue. In the end, it can produce 200-300g of pure Indium with a recycling efficiency of 66.5% to 75%. This is approximately a 10% improvement over the current method in widespread use. If these benefits are factored into improvements in cost, in this competitive display industry, 10% is almost within the range of being able to tip the market.

Currently there are two major sources of Indium tin oxide recycling. The first is ITO glass (such as displays, touch panels, and solar batteries). The second is ITO target materials. The former requires first breaking the materials into pieces, and then a chemical solution is used to filter out impurities and refine Indium tin. Afterwards, from the cladding material equipment, stripping and refinement can be carried out by directly soaking it in a solution.

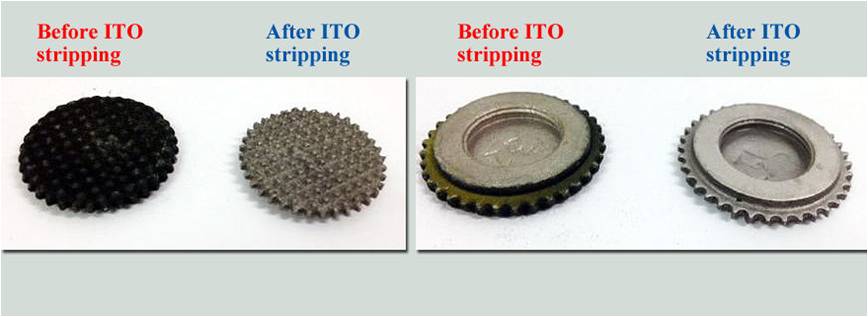

It is also worth mentioning that the UWin Nanotech ITO-900 stripping prescription is almost completely harmless to substrates and allows ITO target materials to “exit gracefully.”

Kenny Hsu points out that all of the vapor deposition equipment used in ITO cladding materials is extremely expensive. Furthermore, the target supplies for carrying out ITO sputtering are also costly, and they must be regularly replaced. However, the replaced target materials can be used as materials for Indium stripping and recycling. ITO-900 can completely strip away Indium time oxide and will not harm the original target materials. It can even reduce sputtering equipment expenses. In addition, the stripping speed is two to three times faster than traditional acid dissolution, so it significantly shortens the reaction time for ITO stripping.

As for Indium tin recycling from ITO glass, currently UWin Nanotech is actively researching and developing a more beneficial optimal procedure, and expects to be able to provide a more economically beneficial and environmentally friendly solution in the near future.

Environmental ITO Recycling Will Establish an Environmentally Friendly Ecosystem for the Display Industry

With the arrival of the multi-screen era, tens of thousands of electronic products with display screens are being produced and sold on the market. These products include smartphones, tablet computers, PCs, TVs, wearable devices, automobile electronics, and smart home appliances. Moreover, in the background of this vigorous industrial development, as indicative of the demand for more Indium metals, on one hand it means that there will be more Indium metal waste. The ITO-900 environmentally friendly recycling technology is a perfect bridge which connects supply and demand.

On the other hand, increasing the Indium recycling rate for ITO materials on the manufacturing end will improve production costs. In addition, valuable Indium metals can be recycled from waste electronic products. Going a step further, soothing the balance between supply and demand for Indium metals will create a sustainable supply cycle for the industry. This can satisfy every prerequisite for environmental protection, and it is a kind of green industrial ecosystem.

|